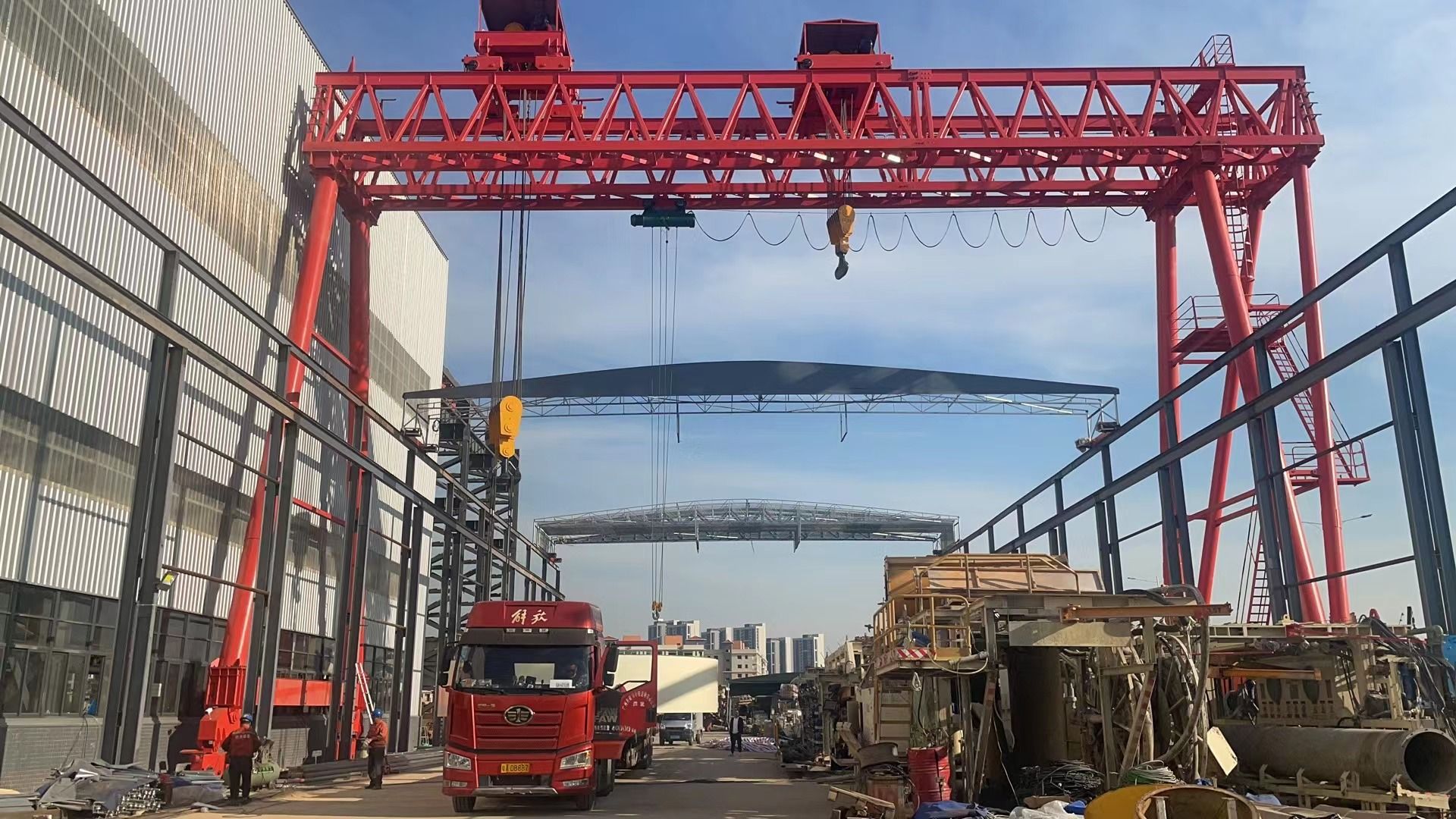

Gantry crane is a heavy-duty handling equipment, commonly used in outdoor cargo yards, workshops, docks, and shipyards. It has the characteristics of large span, flexible operation, and strong carrying capacity. Due to different working environments and lifting requirements, gantry cranes have derived many structural forms. This article will introduce you to the different classifications and characteristics of gantry cranes, which will help you make scientific, economical and efficient selection decisions when purchasing equipment for your company.

1. Main classification and characteristics of gantry cranes

1.According to the main beam structure

Single beam gantry crane

Structural features: There is only one main beam, and the matching electric hoist runs under the beam

Advantages: simple structure, light weight and low manufacturing cost.

Applicable scenarios: small and medium tonnage lifting tasks, open-air or factory locations with low space requirements.

Common lifting capacity: 1 ton - 20 tons.

Double Girder Gantry Crane

Structural features: It consists of two main beams, usually with a trolley running on the top of the beams.

Advantages: strong bearing capacity, large span and high stability.

Applicable scenarios: heavy-load conditions and long-span operations, such as steel structure factories and storage terminals.

Common lifting capacity: 10 tons - 500 tons or even higher.

2. According to the outrigger structure

Box structure

Features: Fully enclosed welded box structure, strong rigidity and good wind resistance.

Applicable environment: strong wind and heavy load working environment.

Disadvantages: high manufacturing cost and heavy weight.

Truss structure

Features: The truss is welded from steel sections, with light weight and low cost.

Applicable environment: outdoor places with large wind loads, such as mountainous areas and seaside areas.

3. By operation mode

Rail mounted gantry crane

Features: running along the laid track, high positioning accuracy

Applicable scenarios: container terminals and large storage yards.

Rubber-tyred gantry crane

Features: Equipped with rubber tires, flexible and autonomous movement

Applicable scenarios: places with frequent site changes and no conditions for ground tracks

4.Classification by purpose

General purpose gantry crane

Features: Equipped with hook, grab or electromagnetic suction cup, suitable for most industrial handling tasks.

Widely used: machinery manufacturing, steel transportation, warehousing and logistics, etc.

Shipbuilding gantry crane

Features: large lifting capacity, wide span and high lifting height.

Strong functionality: it can complete tasks such as hull assembly and large module lifting.

Container gantry crane

Features: Specially used for container loading and unloading operations, usually with automatic grabbing device.

Commonly found in: port terminals, railway freight yards, and logistics parks.

Semi-gantry crane

Features: One side is a leg structure, and the other side runs on the factory track.

Advantages: Suitable for transition areas of workshops or scenarios where there is no track support on one side.

2. How to choose a suitable gantry crane?

The following aspects should be considered when selecting:

1. Lifting capacity and span

When selecting a model, we must first confirm the maximum weight and operating range. Secondly, the span is also a very important factor. It can determine the width of our track laying and will directly affect the structural design of the crane.

2. Place of use

For indoor use, it is recommended to choose a semi-gantry or low-profile structure;

For outdoor use, wind resistance should be considered, and a box-type structure is preferred;

For frequent site movement, it is recommended to choose a tire-type gantry crane

3.Operating frequency and working condition level

For high-intensity and frequent operation occasions (such as ports and steel mills), equipment with double-beam structure and high working level (such as ISO M7 or FEM 4M) should be selected.

4. Spreader Type

According to the shape of the hoisted material, select the appropriate lifting equipment, such as electromagnetic suction cup (steel), grab (bulk material), container lifting equipment (box), etc.

5. Budget and cost performance

On the premise of meeting the technical parameters, choose a cost-effective structure and drive system based on the budget, such as whether to use variable frequency speed regulation and whether to adopt intelligent control.