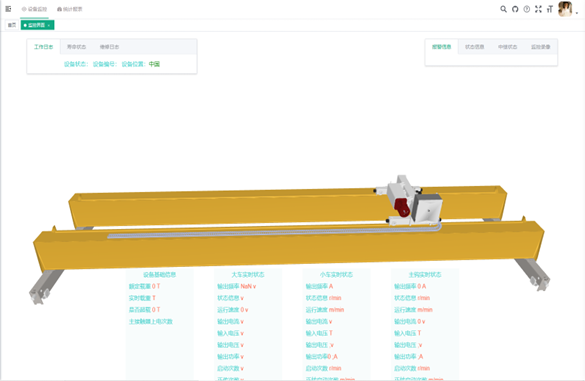

Products Description

Model Number | MATE LH |

Structural Form | Electric Hoist |

Rated Load | 3-100T |

Work Level | M5-M7 |

Equipment Span | 5-50M |

Lifting Height | 6-50M |

Operation Kind | Wired handle, wireless remote control, operation room |

Product Certification | ISO,CE |

Design Standard | GB3811 |

Equipment Color | Yellow, red, blue, other colors available |

Motor Reducer | You can choose European brands such as ABM, SEW, etc. |

Electrical Component | Schneider, ABB, Siemens |

Frequency Changer | Optional(TOSHIBA、SCHNEIDER、ABB、SIEMENS) |

Product Intro

LH electric double-beam hoist crane has been designed in a modular and standardized manner. It has the advantages of light weight, small size, smooth operation, low noise, and maintenance-free. It has the advantages of compact structure, low building clearance height, light weight, and small wheel pressure. It is suitable for transportation, assembly, maintenance, and loading and unloading operations in machine processing workshops, metallurgical auxiliary workshops, warehouses, material yards, power stations, and other places. It can also be used in production workshops in the textile industry and food industry. Its working type is light and medium, the working system is 30-50%, and the working environment temperature is -25℃~40℃. Please do not use it in flammable, explosive, and corrosive media environments. This product has two forms of wired operation and wireless remote control operation. To meet the user's selection needs in various situations.

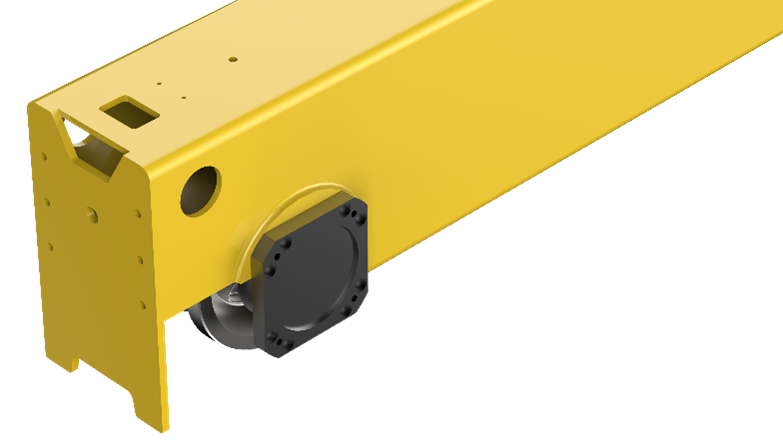

Main Beam Structural Unit

The main beam is an inclined box beam, and the end beam is welded with steel or steel plate. The steel plate is made of Q235-B, Q355B; the vertical deflection is L/1000; all steel plates are pre-treated by shot blasting to meet the Sa2.5 standard; the steel is carefully inspected and cleaned before welding, usually using an automatic welding machine (MIG or semi-automatic welding); all welds are subjected to X-ray non-destructive testing; the welding of each main beam is treated to eliminate internal stress. The surface of the crane is sandblasted, and the primer and topcoat are sprayed within 8 hours, and the paint film thickness is not less than 120μm.

End Beam Structural Unit

The end beam uses welded box beams or rectangular steel pipes as the main beam of the vehicle body structure. Structural flaw detection is carried out after welding. The end beam and wheel combination is processed by CNC boring and milling machines, which improves the installation and assembly accuracy of the equipment, enhances stability, and prolongs service life. The end beam structure is also equipped with an anti-derailment device, a track cleaning device, a buffer device, etc.

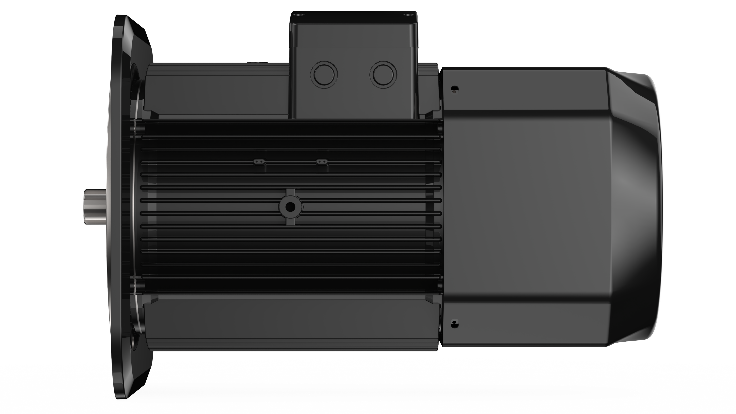

Electric Machine

The motor adopts three-phase AC asynchronous variable frequency brake motor, protection level IP54, H-level insulation, motor working brake S1, with small size, light weight, high market penetration, no carbon brushes, easy maintenance, energy saving and environmental protection.

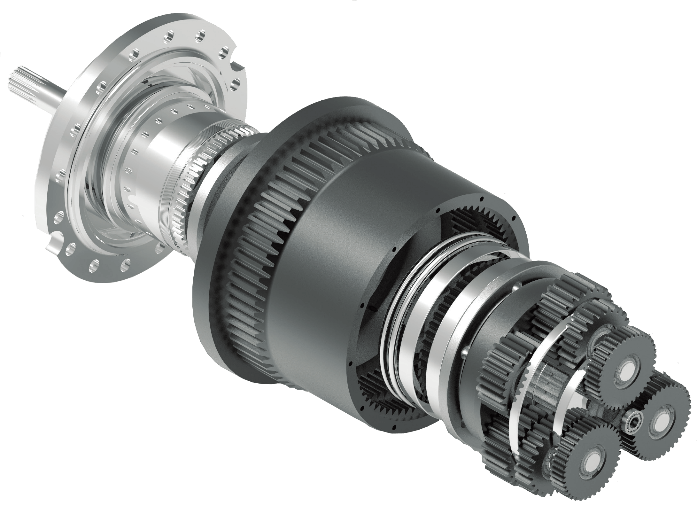

Reduction Gear

The reducer adopts a modular design box, with two options of F series and planetary reducer. The reducer has hardened gears and liquid lubricating oil lubrication, high gear strength, strong wear resistance and low maintenance cost.

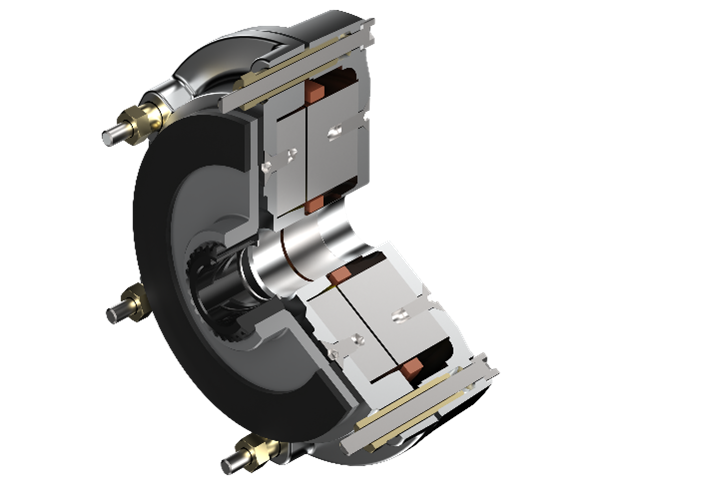

Brake

The brake adopts an electronically controlled disc-type power-off brake, which has a small size, large contact area, high friction, high stability, long service life, low pollution, no asbestos dust, and no oil leakage risk.

Wheel

The wheel is made of alloy steel (QT600, 65Mu, 40Cr, 42CrMo, etc.) with overall tempering treatment, and has the characteristics of light weight, high load-bearing capacity, impact resistance, high tensile strength, wear resistance, long service life, and low wheel pressure.

Bearing

The bearing box adopts cast steel bearing box, and the bearings are mostly spherical roller bearings with high load-bearing capacity and spherical function, which can bear certain axial loads and radial loads at the same time. The friction coefficient of spherical roller bearings is the lowest among all standards, so choosing spherical bearings can improve the load-bearing capacity of the equipment to a certain extent and increase the service life of the bearings.

Reel

Using large diameter seamless steel pipe, material: Q235 or Q355 steel, CNC processed.

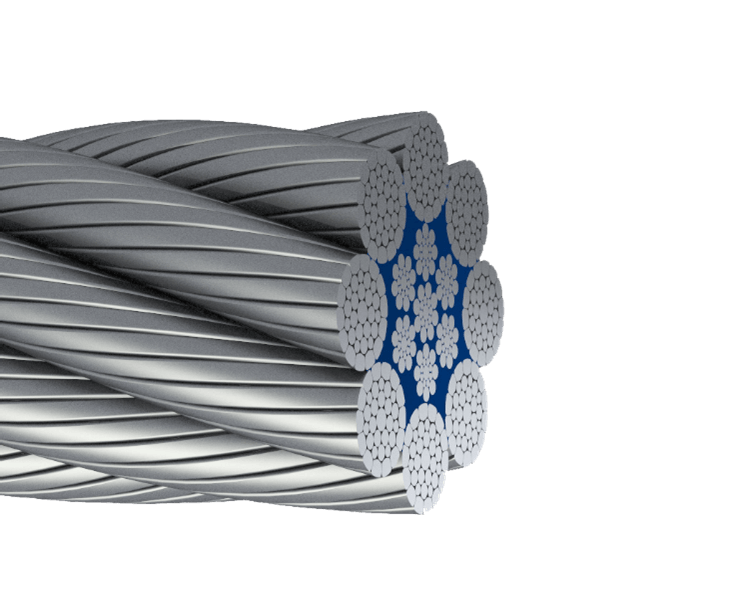

Wire Rope

Wire rope adopts high strength breaking force 2160 wire rope, surface galvanized without oil

Lifting Hook

The hook is made of 35CrMo, can rotate 360 degrees, and is equipped with a safety buckle to prevent slipping. The pulley block is made of high-strength nylon and can be used in explosion-proof environments.

Crane frequency control

The electrical system of the electric double-beam bridge crane adopts frequency conversion control to reduce impact. In the drive part, the frequency converter is used to control the motor to reduce the impact of instantaneous starting current on the power grid and protect the motor. It can save about 20% of electricity. Especially in places where lifting is particularly frequent, it can save about 30%.

The frequency converter can adjust the motor speed to meet the various operating speed requirements of the equipment. For example, in precision assembly, the motor can be adjusted to a low speed to meet the equipment use requirements; or when lightly loaded, the motor speed can be adjusted by the frequency converter to increase the equipment running speed.

Slow start and slow stop

The frequency converter can control the equipment to run from low speed to high speed through speed regulation to achieve the purpose of slow start and slow stop. By slow start and slow stop, the mechanical service life of the equipment transmission parts can be improved, and the inherent vibration frequency of the equipment can be reduced to avoid the damage of the inherent vibration of the equipment to the infrastructure and extend the service life of the infrastructure.

Safety Control Unit

Vehicle Operating Limit

The truck uses the infrared laser limiter, which can be set up 2 distance controls, one short distance control and one long distance control

The principle is that when the crane runs to a certain distance from the obstacle, the running speed drops to a slow speed, which can prevent the accident caused by too fast to brake; If the operation continues, the crane reaches the set stopping distance, the hook stops and cannot continue to move forward, and can only retreat

Car Operating Limit

The truck uses infrared laser limiter or cross limiter, which can be set up two distance controls, one short distance control and one long distance control

The principle is that when the crane runs to a certain distance from the obstacle, the running speed drops to a slow speed, which can prevent the accident caused by too fast to brake; If the operation continues, the crane reaches the set stopping distance, the hook stops and cannot continue to move forward, and can only retreat.

Lifting Opearating Limit

When lifting to prevent the operator improper operation or other reasons, set up a highly protective device, can effectively protect the user's life product safety.

Mechanical height zone stopper

The upper limit can set 2 distances, one is to slow down and one is to stop.

The principle is that when the hook rises to the set and there is a certain distance from the stop, the hook speed drops to a slow speed, which can prevent the accident caused by too fast and too late braking; If it continues to rise, when the hook reaches the set stop area, the hook stops and cannot continue to rise, but can only fall.

Lifting Impact Limit

Using a fixed limit device, as long as the hook is lifted to the place where the limit is set, the hook touches the limit switch, the switch works, and the hook cannot be lifted.

OverLoad Protection

The lifting mechanism is equipped with a weight sensor, which can detect the weight of the goods during the lifting process to avoid overload caused by unclear weight of the goods, and overload will lead to a variety of hazards, so the selection of high-precision weight sensors is very important for the equipment.

When the crane is carrying more than the full load, it automatically stops, and can only land, not rise.

Overheat Protection

The motor is equipped with a thermal sensor, which can monitor the temperature of the motor, heat up when the motor exceeds the allowable range of the equipment due to the frequency of use, and can be forced to stop by the electronic control system, and can be used again when the temperature of the motor is cooled, so as to avoid the motor overheating resulting in reduced or damaged motor life.

Overcurrent Protection

The motor can be protected by the overcurrent protection function of the inverter to prevent the damage caused by overcurrent to the motor.

Audible And Visual Alarm

The crane supports 3 color red, green and yellow sound and light alarms

It can show the position of the crane when the crane is running, and remind the staff of the workshop to be careful of the collision.

When the crane has a problem, it will light different colors according to the fault to remind the operator.

End Beam | Electromagnetic Brake | Brake Motot | Planetary Reducer |

Wire Rope | Pulley

| Reel

| Cross Limit

|

Mechanical Gear Limit

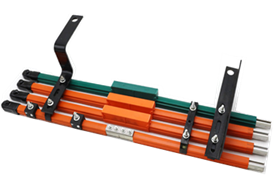

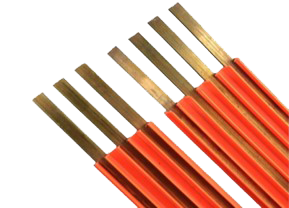

| Unipolar Slide Line | Seamless Sliding Line | Cab

|

Remote Control Unit

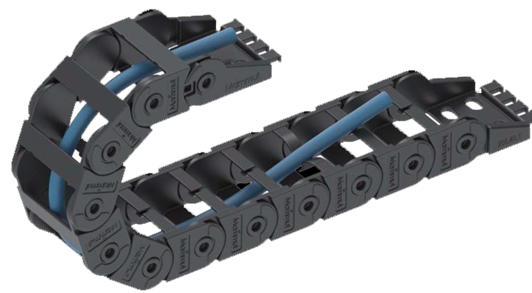

| Towing Cable

| Industrial Cloud

|

Tags: MATE LH Electric Crane Double Girder Bridge Crane Industrial Bridge Cranes

Technical parameter

Technical parameters refer to the relative data obtained for a certain thing in the specified inspection environment, usually refers to the performance test report made in the design or production process, including physical parameters, performance indicators and reliability parameters, which describes the specifications, performance, function, structure, size, use environment and other specific data or indicators of a product, equipment, parts or components. These parameters play an important role in the process of product design, production and use, directly affecting the performance and quality of the product, but also an important consideration for users when choosing and using the product.